Process Technologies

Advance Surface Modification

ALD

Nano-Composites

PECVD

Plasma Surface Activation

Silination

Typical Industries

Genomics Research

Hearing Industries

Medical Devices

Optics

R&D / Educational

Semiconductors

Sensors

Wearable Manufacturing

Applications

Adhesion Promoters

Assays

Glassware

Hearing Aids

Imprint

MEMS

Microfluidic Devices

Oleophobic Coatings

Printed Circuit Boards

Protective nano-coating

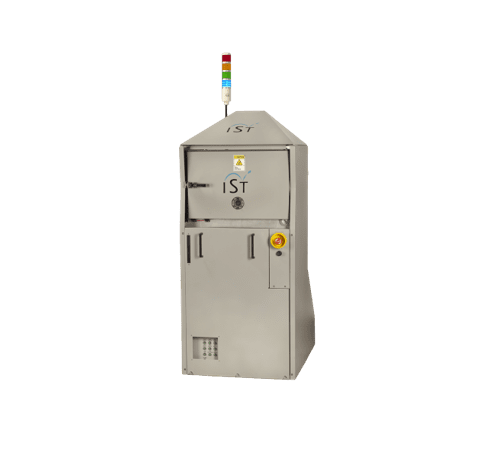

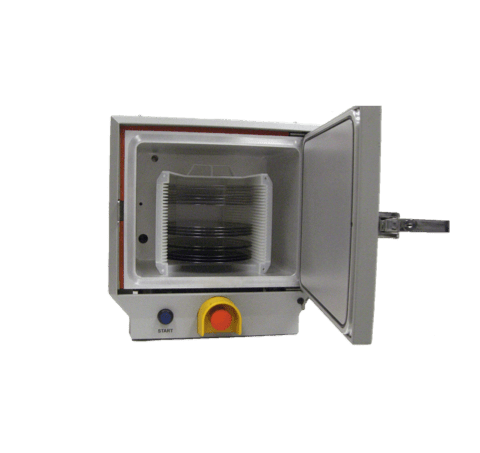

The RPX-540 can deliver up to 5 separate vapor sources to a variety of substrates. It has a configurable process chamber with the flexibility to coat large objects like a laptop or many smaller shapes and sizes. For planar products, it can deliver the gases through fin-style applicators that can coat up to 21 square feet per batch. The RPX-540 has standard a 1000W RF plasma for additional in-situ surface modification. The gases are formed and delivered in the Vapporrix system, which is a proprietary technology invented by IST. The Vapporrix delivery is fully enclosed OSHA certified gas cabinet with exhaust which allows the safe use of highly flammable metal-organics commonly required for ALD. The RPX-540 system is compact and does not require side access for maintenance or operation so multiple systems can be positioned side-by-side to maximize output of your floor space. The RPX-540 has an integrated fume hood exhaust over the process chamber creating an air curtain between the user.

- 60 liter Chamber (Capacity Reference: two 200mm Wafer Cassettes, four 6” wafer cassettes or 13 300mm wafers).

- 5 Liquid Precursors (Optional Bubbler Delivery).

- Flexible plasma configurations: 1000W @ 40KHz …or…. 600W @ 13.56MHz ….or….. 1000W @ 13.56MHz Pulse Mode

- Solid structural Aluminum chamber construction which is corrosion proof.

- Semiconductor style surface mount vapor components for quick component exchanges.

- Multi-zone (chamber, vapor delivery modules, precursors) heating for a controlled temperature gradient of the entire chemical delivery system.

- OSHA compliant gas cabinet enclosure for all precursors.

- Ventilation Exhaust Hood for added safety to operational personnel. Ideal for working with thiols of other aromatic precursors.

- Complete hardware and software interlocks.

- Multi-User authorizations for restricted operation but select personnel

- Windows-11 OS allows for computer networking of all log files.

- Simplified facility requirements for easy maintenance and low cost installations.

- On-site startup support by IST personnel.

- Free process recipes for all know precursors of interests.

- CE Mark / Semi-S2 / Semi-S8 Certifications.